Design

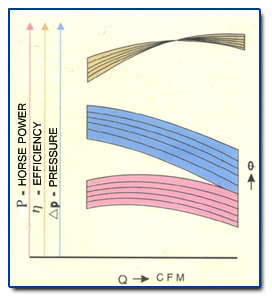

Energy Efficient Fans

Light Weight

Tough

Corrosion & Erosion Resistance

Durability

‘Impact’ FRP Fans have a very high strength to weight ratio compared to similar products available due to the intelligent FRP lay-up pattern. Thousands of our fans are working tirelessly worldwide, delivering air efficiently, without the need to replace or repair over the years.

Vibration Free

‘Impact’ Airfoil Fan blades are ‘moment balanced’. Fan hubs are dynamically balanced per ISO standards and Fan assemblies are statically balanced to ensure vibration-free operation for years.

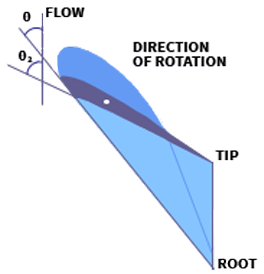

Advanced Blade Manufacturing

To ensure a higher quality product for our customers, we have adopted a state-of-the-art manufacturing process using advanced manufacturing facilities and stringent quality standards. ‘Impact’ FRP Fan blades are made very precisely using moulds. Both, casting and extrusion manufacturing processes have expensive tooling and face a challenge in generating blade profiles with high twist and camber characteristics. This has restricted conventional metallic/aluminum fans to retain a low camber in their design. Furthermore, there is a high level of inconsistency in manufacturing tolerances or dimensional stability of the metallic blades causing further deterioration of fan performance. In order to prevent these inconsistencies, ‘Impact’ Fans are manufactured using advanced vacuum infusion technology, enabling uniform weight and wall thickness.

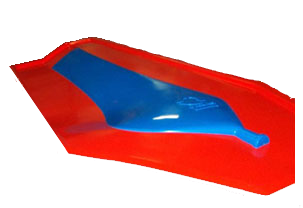

Vacuum Infusion Process (VIP)

Vacuum infusion takes a different approach, in that a vacuum is drawn while the materials are still dry. Resin is then infused using vacuum pressure. Instead of drawing excess resin out, VIP starts with none and infuses resin in. Excess resin, if any, is eventually drawn out in the vacuum line. As a result resin is introduced very precise amounts. Fan blades are manufactured from Vacuum Infusion Process (VIP) to achieve the following:

- Better fibre to resin ratio

- Lower and more consistent blade weight

- Uniform wall thickness

- Higher aerodynamic accuracy, consistency and superior surface finish

- Increased blade strength

- Maximized fibre and resin properties

‘Impact’ Fans FRP blades are cured using a very efficient drying process. State-of-the-art dynamic balancing techniques and machines are used for proper balancing to ensure that the operation of the fan assembly is vibration free. The moment value of different fan blades is electronically synchronized by the Match Moment machine. Thus perfectly manufactured ‘Impact’ Fans offer trouble-free superior performance, increased efficiency and ease of installation as compared to conventional metallic & GRP fans.