Energy Efficient Axial Flow Fans

Design

Energy Efficient Fans

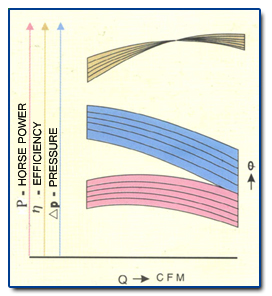

More air with less power means less operating costs. ‘Impact’ Energy Efficient Fans provide 10 – 40% power savings as compared with other metallic / GRP Fans. Installation of ‘Impact’ Fans in newly constructed equipment reduces initial equipment costs along with operational costs.

Light Weight

‘Impact’ Axial Flow Fans are light weight and hollow and allow easy handling and maintenance, resulting in less down time. Furthermore, the life of the gear box, motor and bearings are extended due to a reduction in the moment of inertia.

Tough

FRP construction of ‘Impact’ Fans with an intelligent, seamless lay-up pattern provides resilient, dependable blades with high fatigue strength. Impact blades have stood the test of extreme conditions like cyclones and high wind loads. Our 10 year old blades withstood wind loads of 135 mph winds in Vizag, India without need for replacement even when the surrounding infrastructure had all blown away.Low Noise:’Impact’ fans’ unique airfoil design reduces the operational fan noise level considerably compared to conventional metallic / GRP Fans.

Corrosion & Erosion Resistance

Durability

Vibration Free

Advanced Blade Manufacturing

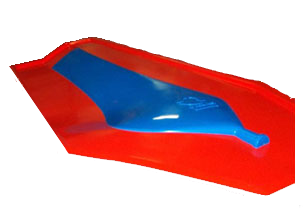

To ensure a higher quality product for our customers, we have adopted a state-of-the-art manufacturing process using advanced manufacturing facilities and stringent quality standards. ‘Impact’ FRP Fan blades are made very precisely using moulds. Both, casting and extrusion manufacturing processes have expensive tooling and face a challenge in generating blade profiles with high twist and camber characteristics. This has restricted conventional metallic/aluminum fans to retain a low camber in their design. Furthermore, there is a high level of inconsistency in manufacturing tolerances or dimensional stability of the metallic blades causing further deterioration of fan performance. In order to prevent these inconsistencies, ‘Impact’ Fans are manufactured using advanced vacuum infusion technology, enabling uniform weight and wall thickness.

Vacuum Infusion Process (VIP)

- Better fibre to resin ratio

- Lower and more consistent blade weight

- Uniform wall thickness

- Higher aerodynamic accuracy, consistency and superior surface finish

- Increased blade strength

- Maximized fibre and resin properties