Mechanically forced-draft or induced-draft cooling towers are used to remove the heat absorbed in circulating cooling water systems. The Fan is the most essential component of the cooling tower. Impact fans regularly provide efficiencies of 15-40% over other makes in wet cooling applications like cooling towers. All of our cooling tower fans installed worldwide are saving energy at the rate of 250MW. Impact fans provide a less expensive and quick fix to reducing the auxiliary power consumption in a plant.

- Available Sizes: 2 ft. to 60 ft.

- Number of Blades: 4 to 12

- Static Pressure: Up to 1 inch of WG (25 mm)

- Air Flow: Up to 3,000,000 CFM

- Fan RPM: Up to 1440

- Operating Temperature Range: – 40ºF to 248ºF

Features & Benefits

FRP FAN

- FRP Impeller

- Efficient operation.

- More air with less power or reduced power for same air.

- Optimal operational cost.

- Economical initial cost

- Impellers are dynamically balanced to ISO – 1940 Grade 6.3 or 2.6.

- Fans available with or without seal disk to suit Induced Draft or Forced Draft applications.

- Blade airfoil with high lift and low drag.

- Small fans up to 6 ft. (1800 mm) diameter are dynamically balanced as per ISO–1940 Grade 6.3.

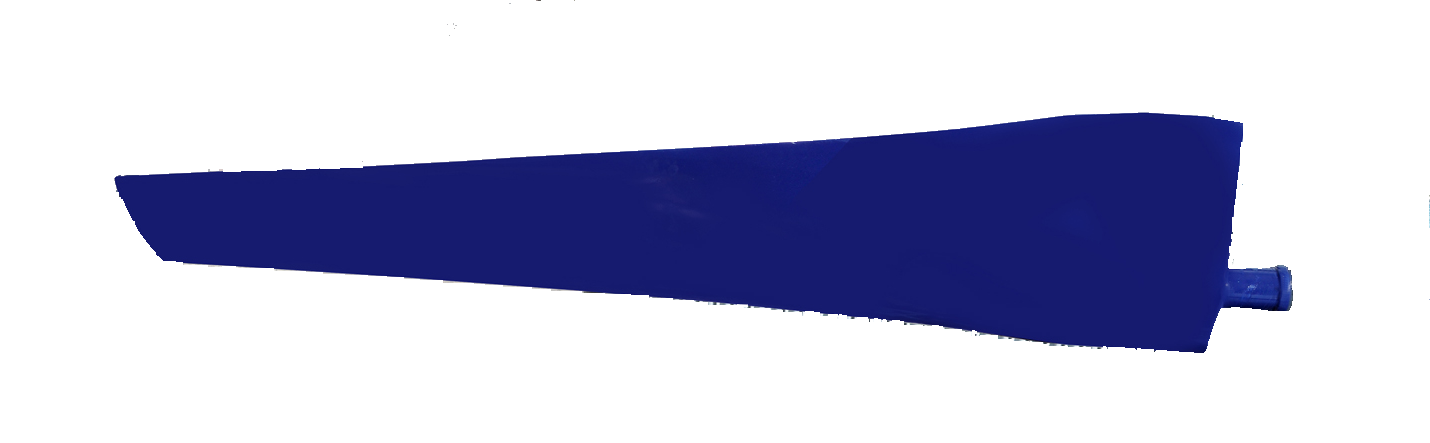

FRP BLADE

- Blade airfoil with high lift and low drag.

- Uniform air flow over entire blade length.

- UV protection and Fire retardant FRP Blades.

- Corrosion and Erosion resistant FRP Blades.

- Special leading edge protection.

- Moment balanced to ensure inter-changeability.

- Ideally shaped for standard and low noise fans.

- Convenient blade tip angle setting.

- Individual moulds for each blade size to maintain high efficiency

- Special blade shape at root to minimize swirl without seal disk.

SEAL DISK

- One Piece Statically Balanced.

- Segmented availability for ease in handling and transportation.

- Each segment moment balanced.

- Prevents swirl.

- UV resistant.

HUB

- Easy to install, handle and maintain

- Hot dip galvanized double plated.

- Hubs are dynamically balanced to ISO – 1940 Grade 6.3

- Compatible with most standard taper lock bushings and custom specified drive shafts.

- Optional welded hubs to reduce initial cost.

Standard Material of Construction

Blades :

- Fiber-Glass Reinforced Plastic using fire retardant resins.

Hub :

- Plates : Hot Dipped Galvanised Mild Steel.

- Fasteners : Galvanized Steel / SS-304.

- Blade Holding blocks : Cast Aluminum Alloy LM-6 / Cast Iron FG-200.

- Center Bush : Cast Iron FG-200

- Seal Disk: Fiber-Glass Reinforced Plastic