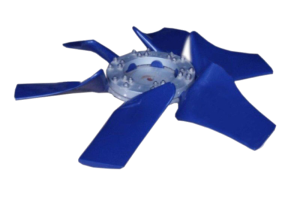

Industrial Ventilation is a method of controlling airborne toxic chemicals or flammable vapours by exhausting contaminated air away from the work area and replacing it with clean air. ICS has developed wide range of FRP Impellers to suit Industrial Ventilation & Exhaust Applications.

- Available Sizes: 2 ft. to 6 ft.

- Number of Blades : Up to 16

- Static Pressure : Up to 4 Inches of WG

- Air Flow : Up to 1,00,000 CFM

- Fan RPM :Up to 3000

- Operating Temperature Range:-40ºF to 248ºF

Features & Benefits

- FRP Impeller

- High efficiency of operation.

- More air with less power

- Reduced power for same air.

- Optimal operational cost.

- Economical initial cost

- Impellers are dynamically balanced to ISO – 1940 Grade 6.3 or 2.6 upon request.

FRP BLADE

- Blade airfoil with high lift and low drag.

- Uniform air flow over entire blade length.

- Special leading edge protection.

- Corrosion and Erosion resistant FRP Blades.

- UV Resistant blades.

- Blades are moment balanced to ensure inter-changeability.

- Ideal blade shapes for standard and low noise Fans.

- Convenient blade tip angle setting.

- Individual moulds for each blade size to maintain high efficiency.

HUB

- Easy to install light weight Aluminum Alloy (Grade LM6) Hubs.

- Optional MSHDG Hubs.

- Hub to suit standard taper lock bushings or custom specified drive shafts.

- Ease in handling and maintenance.

Standard Material of Construction

Blades :

- Fibre Glass Reinforced Plastic using Polyester or Epoxy Resin

Hub :

- Support Plates/ Hub Body: Cast Aluminum Alloy LM -6

- Fasteners: Galvanized Steel/ SS304

- Center Bush: Cast Iron FG 200